Sauder assembly instructions provide a comprehensive guide for constructing furniture, ensuring durability and functionality․ They are designed to help users assemble products efficiently and correctly, fostering confidence in DIY projects․

1․1 Overview of Sauder Furniture and Its Popularity

Sauder furniture is renowned for its high-quality, ready-to-assemble designs, offering a perfect blend of style, functionality, and affordability․ The brand has gained widespread popularity due to its durable materials and user-friendly assembly processes․ Sauder’s commitment to innovation and customer satisfaction has made it a trusted name in the furniture industry․ Its products cater to diverse tastes, ensuring a seamless fit into modern and traditional settings alike․ This reputation for excellence has solidified Sauder’s position as a leader in the market, making its assembly instructions a valuable resource for DIY enthusiasts․

1․2 Importance of Assembly Instructions for Sauder Products

Sauder assembly instructions are essential for ensuring the correct and safe assembly of furniture․ They provide clear, step-by-step guidance, helping users avoid errors and understand the process․ Proper assembly is critical for the stability, functionality, and longevity of the product․ By following the instructions, users can achieve professional results, ensuring their furniture meets safety and quality standards․ These guides empower individuals to complete projects confidently, saving time and effort while protecting their investment in Sauder furniture․

Understanding the Sauder Assembly Instructions PDF

The Sauder Assembly Instructions PDF is a detailed guide providing clear, step-by-step instructions for assembling Sauder furniture․ It includes diagrams, part lists, and safety tips to ensure success․

2․1 Structure and Layout of the PDF Document

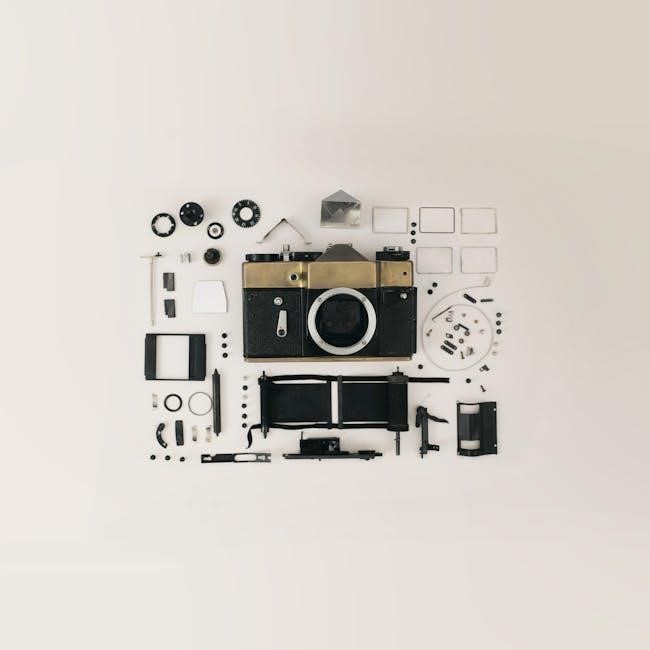

The Sauder Assembly Instructions PDF is organized into clear sections, starting with an introduction and table of contents․ It includes numbered steps, diagrams, and lists of required tools and materials․ The document features visual aids like exploded views to illustrate part assembly․ Safety precautions and troubleshooting tips are highlighted for easy reference․ The layout is user-friendly, with bold headings and bullet points to enhance readability․ Each page focuses on specific assembly stages, ensuring a logical progression from preparation to final product completion․

2․2 Key Components of the Instructions

The Sauder Assembly Instructions PDF includes essential elements like detailed step-by-step guides, high-quality diagrams, and a comprehensive list of required tools and materials․ It also features safety tips, troubleshooting advice, and a glossary of technical terms to ensure clarity․ The instructions emphasize proper sequencing of assembly steps and provide visual aids like exploded views to simplify complex processes․ Clear headings, bullet points, and highlighted warnings make the document easy to navigate, ensuring users can follow along confidently and efficiently․

Tools and Materials Required for Assembly

Screwdrivers, Allen wrenches, and bolts are essential tools․ Materials include screws, dowels, and wood glue․ Ensure all items are ready to streamline the assembly process․

3․1 List of Essential Tools

Assembling Sauder furniture requires specific tools to ensure accuracy and efficiency․ Essential tools include a screwdriver, Allen wrench, and a rubber mallet․ A tape measure may also be useful for verifying dimensions․ Additionally, clamps can help hold pieces in place while assembling․ Ensure all tools are readily available to avoid delays․ Having these tools organized will make the assembly process smoother and less stressful․ Proper tools are crucial for achieving a sturdy and professional finish․ Gather all necessary tools before starting to save time and effort․

3․2 Additional Materials Needed for Specific Products

Depending on the Sauder product, additional materials may be required for assembly․ These could include wood glue for added stability, extra screws, or specific fasteners․ Some items may need wall anchors for secure installation․ Adjustable feet or leveling pads might also be necessary for uneven surfaces․ Safety gear like gloves or safety glasses is recommended when handling power tools․ Always refer to the Sauder assembly instructions PDF for product-specific material requirements to ensure a successful assembly process․

Step-by-Step Assembly Process

The Sauder assembly instructions guide users through a detailed, sequential process․ Begin by preparing the workspace and organizing components․ Follow each step meticulously to ensure accuracy and stability․

4․1 Preparing the Workspace

Begin by clearing a large, flat, and stable workspace․ Cover the area with a drop cloth or old sheets to protect it from scratches or damage․ Ensure good lighting to see small parts clearly․ Organize all tools and components neatly, referencing the parts list in the Sauder assembly instructions․ Double-check that all items are included and undamaged․ If needed, label components to avoid confusion later․ Keep children and pets away to maintain focus․ Wear protective gloves if handling sharp materials․ Proper preparation ensures a smooth and error-free assembly process․

4․2 Following the Sequence of Assembly

Adhere strictly to the sequence outlined in the Sauder assembly instructions․ Begin with the base or largest components, ensuring each step is completed before moving on․ Use the parts list to verify all items are included and organized․ Carefully read each instruction and study diagrams to understand the next action․ Avoid skipping steps, as this can lead to misalignment or instability․ Double-check connections and alignments before tightening bolts or screws․ Following the sequence ensures a sturdy and functional final product, minimizing the risk of disassembly or corrections․

Tips for Successful Assembly

Work at a steady pace, organizing parts beforehand․ Use the correct tools and follow instructions carefully․ Double-check each step before proceeding and take breaks if needed․

5․1 Common Mistakes to Avoid

Common mistakes include misaligning parts, skipping steps, or using incorrect tools․ To avoid these, always double-check hardware against the instructions․ Organize components beforehand and ensure the workspace is clear․ Miscounting screws or forcing pieces together can damage the product․ Take your time to align edges properly․ If unsure, refer back to the manual or diagrams․ Avoid over-tightening, as this may strip screws․ Using a checklist can help track progress and prevent overlooked steps․ Addressing issues early ensures a stable and secure assembly․

5․2 Time Management and Organization

Effective time management and organization are crucial for a smooth assembly process․ Start by setting a realistic timeline and gathering all necessary tools and materials․ Organize components in labeled containers to avoid confusion․ Divide the project into manageable steps, focusing on one section at a time․ Keep the workspace clean and clutter-free to prevent losing small parts․ Allocating specific time slots for each task ensures progress without rushing․ Proper planning reduces stress and helps complete the assembly efficiently, resulting in a sturdy and well-constructed final product․

Safety Precautions

Always wear safety glasses and a dust mask when sanding or drilling․ Ensure a stable workspace and keep loose clothing tied back to avoid accidents․

6․1 Handling Tools and Materials Safely

Always wear protective gloves and safety goggles when handling tools and materials to prevent injuries․ Use tools only for their intended purposes and follow proper lifting techniques to avoid strain․ Ensure the workspace is well-lit and free from clutter to minimize hazards․ Keep sharp objects and small parts out of reach of children․ Regularly inspect tools for damage and replace worn or broken items promptly․ Properly store materials to maintain stability and prevent accidental tipping․

6․2 Ensuring Stability and Balance of the Assembled Product

Ensure the assembled product is stable by checking all surfaces are level and even․ Use the provided hardware correctly to secure parts firmly․ Avoid over-tightening, which may cause warping․ Place the product on a firm, flat surface to prevent wobbling․ Double-check all joints and connections for proper alignment and tightness․ If necessary, adjust legs or bases to achieve balance․ This ensures the product remains sturdy and safe for use, preventing accidental tipping or instability over time․

Troubleshooting Common Issues

Troubleshooting common issues during assembly involves identifying errors, checking hardware for proper fit, and ensuring all parts align correctly․ Addressing problems early prevents further complications․

7․1 Identifying and Resolving Assembly Errors

Identifying assembly errors early is crucial for successful furniture assembly․ Common issues include misaligned parts, missing hardware, or incorrect step sequencing․ To resolve these, carefully review the instructions, ensuring all components are properly aligned and securely fastened․ If a part doesn’t fit, double-check its orientation or consult the Sauder assembly instructions PDF for clarification․ For persistent issues, contact customer support for assistance․ Addressing errors promptly prevents further complications and ensures a sturdy, functional final product․

7․2 Adjustments and Corrections During Assembly

During assembly, minor adjustments may be necessary to ensure proper fit and alignment․ If parts feel loose or misaligned, gently tighten hardware or reposition components as needed․ Use shims or foam pads to stabilize uneven surfaces․ If corrections require disassembling, do so carefully to avoid damaging parts․ Always refer to the Sauder assembly instructions PDF for guidance․ Making adjustments early prevents structural issues and ensures a stable, professional-looking final product․ Taking the time to correct alignment enhances both functionality and aesthetics․

The Sauder assembly instructions PDF guides users through a seamless assembly process, ensuring satisfaction and durability․ Proper assembly fosters confidence and a sense of accomplishment, guaranteeing long-lasting functionality․

8․1 Final Check and Inspection of the Assembled Product

After completing the assembly, conduct a thorough inspection to ensure all parts are securely in place․ Verify that no screws or bolts are loose and that all components align properly․ Check for any visible damage or defects in the finish․ Ensure the product is stable and functions as intended, such as drawers opening smoothly or shelves being level․ Review the instructions one last time to confirm no steps were missed․ Test any movable parts and clean the surface before use․ This final check ensures both safety and satisfaction with the assembled product․

8․2 Benefits of Proper Assembly and Maintenance

Proper assembly ensures your Sauder furniture is durable, functional, and safe to use․ Following the instructions closely results in a sturdy and aesthetically pleasing product that meets its intended purpose․ Regular maintenance, such as cleaning and tightening hardware, extends the lifespan of the furniture․ A well-assembled piece enhances your space and provides long-term satisfaction․ Additionally, proper assembly prevents potential safety hazards, ensuring stability and balance․ This attention to detail fosters confidence in your DIY skills and ensures your Sauder furniture remains a valuable asset for years to come․